cotton picking machine mechanism

It is equipped with a bigger hopper which can extend the picking time greatly and boast large capacity in the field. Following are the basic components of a mechanical picker.

Beating Mechanism With Sley Loom Weaving Weaving Loom

Early on some mechanical engineers tried to pick the cotton with pneumatic mechanisms that acted like giant vacuum cleaners.

. The Cotton Picking Machine - New Model is 20 faster than the old model. By using Design Expert 806 to optimize the solution when the working angle of the pick-up mechanism is 2731 the depth of the pick-up mechanism is 730 mm. Here are some general recommendations for operators of cotton harvesters in California.

The current cotton picker is a self-propelled machine that removes cotton lint and seed seed-cotton from the plant at up to six rows at a time. No longer would farmers have to rely on laborers to go out and work the fields all day picking cotton off the bollsinstead they could invest in a cotton picker that. Recently pneumatic cotton picker can be used as a mechanism which would reduce the harvest cost and maintain the cotton fiber quality comparing with the.

There are two types of pickers in use today. Early Cotton Harvesting Machine. It has a super long time continuous working capacity.

Some early prototypes tried to harvest with pneumatic mechanisms some tried to adopt threshing machine others tried static electricity or mechanical fingers. Others tried to adapt grain threshing machines to cotton. Using the Cotton picking machine the speed is increased from 50 to 200 as compared to manual.

The performance for the machine is stable and reliable. 11 Need of harvesting machine In conventional harvesting process the. It is available with suction feed as auxiliary attachment.

The development of the mechanical cotton picker goes back to the early 1930s and its proliferation and improvement in the decades that followed made for significantly easier harvesting of cotton. This machine is 30 light in weight and also consumes 20 less power than the old model. Finally a flow of air would suck the cotton off the doffer.

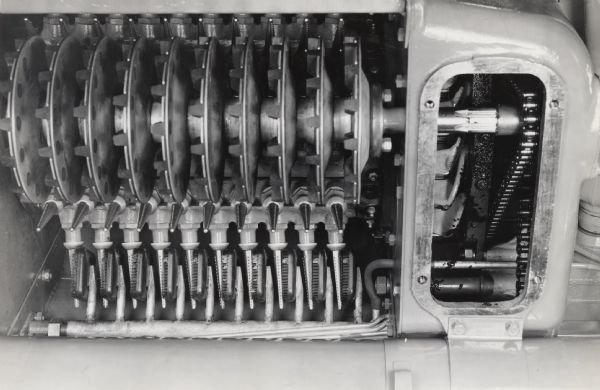

A spindle was a rod or prong that could poke into a cotton boll and rotate to spool up the fibers easily pulling away the boll. The modern mechanical cotton harvester is a large machine w. Then a doffer which acted like a large comb would strip the cotton from the spindle.

As name suggest it harvest cotton flower one at a time using machine vision technique and robotic arm. The machine is available in two models. Using the Cotton picking machine the speed is increased from 50 to 200 as compared to manual picking efficiency.

1Traditional Cotton Harvesting Process Traditionally a small scale farmer used to deploy 2-3. But in India cotton harvesting is mostly done with human efforts. Before starting the mechanical harvester put the mechanism or transmission in the neutral or park position.

Machine has the capability and the economic value for fulfilling the needs of farmers having small land holdings less than 2 acres. In 1850 the first cotton harvesting machine was patented. Mostly cotton harvesting in these country is carried out by large machineries.

The cotton picking machine dramatically increases the cotton - picking efficiency. Ii Devices to remove the cotton from open bolls. Easily pickingsave the labour cost.

Skillful operation is necessary f nd around the machine and f on. This stripper saves cost involved in manual labour and eliminates drudgery for women and children. This machine is cost effective and easy to maintain and repair for the farmer.

One is the stripper picker primarily found in use in Texas. High and new technologies are widely used in the self-propelled picker. This picking machine is manufactured with quality tested material and advanc.

The working angle of the clamping and conveying device is 3833 the recovery rate is 939 and the damage rate is 893. It processes 400 kg cotton per hour. It improves the quality of cotton.

The cotton picking machine dramatically increases the cotton - picking efficiency. I An arrangement for guiding the plants into the picking zone and providing necessary support while the seed cotton is being removed. In a cotton picker of the pneumatic type a wheel supported movable platform a support at the forward end of said platform having a swivel joint at its upper end a.

It has a lasting service life. Others tried static electricity. Then over the next century over 1800 patents were issued for cotton harvesting schemes.

System consist of camera to take image of cotton robotic arm to pick cotton from plant image. Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode. Introduction of Cotton Picking Machine.

Our firm specializes in providing an excellent range of Cotton Picking Machines. As the machines cost is unbearable for small scale farmers. A cotton picking machine comprises a chassis for moving the machine in a traveling direction a vacuum pump provided to create a predetermined vacuum and a cotton picking unit including a cotton picking head supported by the chassis.

They are also found in Arkansas. In proposed work Cotton Flower Picking Machine Based on Machine Vision Technique is present. Cotton Picking Machine is an innovative Cotton harvesting tool for the Indian Farmers.

Others tried mechanical fingers or prongs to remove the cotton lint fibers to be spun into cloth. Cotton picking machines have spindles that separate the seed cotton from the burrs which are attached to the stems of each plant. DC12v - Electric Motor.

The cotton picking head includes upper and lower vacuum compartments both in fluid communication with the vacuum pump and connecting. Offering Cotton Picking Machine Battery Operated - Voltage. The team went to Mansukhbhai Patel who has made the cotton stripper machine.

At that point a mechanism called a doffer removes the seed cotton from the aforementioned spindles and directs the seed cotton on to a conveyor system.

Positive Tappet Shedding Mechanism Positive And Negative Positivity Negativity

Classification Of Picking Mechanism Loom Weaving Shuttle Loom Loom

Cotton Harvester The Portal To Texas History

Dobby Shedding Mechanism Dobby Card Patterns Jacquard

Cotton Harvesting Wessels Living History Farm

International Harvester Cotton Harvesters Octane Press

How Do Cotton Harvesting Machines Work

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion

Shows The Construction Of The Tappet Of 3 Up And 1 Down Twill Weave Weaving Machine Weaving Textiles Weaving

Cotton Picker Mechanism Photograph Wisconsin Historical Society

Pin By Omar Eldeeb On غزل Cotton Yarn Fiber Hanging Yarn

Fm E 2 Lesson 18 Cotton Pickers Construction And Working Principles

Cone Under Picking Mechanism Flow Chart Chart Cone

Cotton Picking Machine The Portal To Texas History

Tappet Shedding Mechanism Dobby Card Patterns Jacquard

Cotton Harvester Machine Britannica

Jacquard Shedding Mechanism Card Pattern Card Patterns Kinds Of Fabric